At the height of production in the late 17th century, there were no fewer than 33 potteries in Delft. The process of making and firing earthenware could take as long as two weeks, from preparing the clay to cooling the finished product and preparing it for sale.

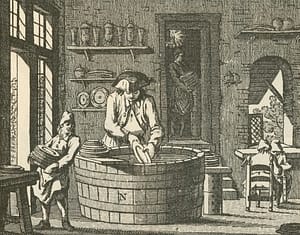

Delftware was made using a clay mixture comprised of local clay, fattier clay from Germany, and dry marl from the Tournai region of Flanders or England. Before being glazed, the pots underwent an initial firing. Stokers would heat the kiln to temperatures ranging from 800-1000°C. The wares became hard and acquired a buff colour during firing. They were then dipped in a bath of white, opaque tin glaze to completely cover them and decorated with colour pigments.

The famous blue pigment is cobalt oxide mined in Germany. When painted onto the object, it appeared dark grey, but during the second firing, it transformed into a bright blue. The purer the cobalt, the brighter the blue. To add extra gloss to objects, they could be covered with a layer of transparent lead glaze in a process known as kwaarten.

The pots were stacked in saggars within the kiln to protect them from flames and smoke during the firing process. The items were separated in the saggar using triangular pegs. These left small imprints in the glaze on the base or back of the pot. These imprints are, therefore, distinctive features of antique Delftware. The same applies to small imperfections, such as chipped glaze. Chips serve as useful aids for identification. Dutch Delft body typically exhibits a warm, yellow-buff colour and has a slightly gritty texture resembling sand or brick.

Another distinctive feature of antique Delftware is the presence of tiny, discoloured spots known as ‘peppering.’ These were caused by air bubbles trapped in the glaze, which exploded while the piece was being fired in the kiln. If you encounter Delftware with a very smooth, unchipped surface, your suspicions should be immediately aroused. Perfect examples are extremely rare, and since these objects were made for practical use, you should expect to find chipping on the rim and foot-rim.

Most of the many factories in Delft did not mark their wares. However, during the second half of the 17th century, some potteries began identifying their products, but this practice was largely abandoned during the 18th century.

Tin glaze technique was used in Delft until around 1850. That is why we refer to objects made between 1620 and 1850 as antique Delftware. After 1850 Delftware was made using another technique and is known as modern Delftware.